1. Introduction

In today’s world of custom merchandise, vibrant t-shirts, personalized mugs, and durable promotional items are everywhere. But have you ever wondered how these long-lasting, colorful designs are made? One technique behind this revolution is sublimation printing.

Whether you’re a small business owner, a designer, or just curious about how modern printing works, understanding sublimation printing can open new doors for creativity and customization. In this guide, we’ll break down everything you need to know about sublimation — what it is, how it works, its pros and cons, and how it compares to other printing methods.

2. What Is Sublimation Printing?

Sublimation printing is a heat-based printing process that transfers dye onto materials using a chemical process where the dye turns directly into gas without becoming liquid. This results in vibrant, high-definition prints that are embedded into the material rather than resting on top of it.

In simpler terms, sublimation allows ink to become part of the fabric or substrate. Unlike screen or vinyl printing, which can peel or crack over time, sublimation designs are permanent and fade-resistant.

This technique is especially effective on polyester fabrics and polymer-coated products like mugs, plates, and phone cases.

3. How Does Sublimation Printing Work?

Sublimation printing is a four-step process that ensures precision, durability, and vivid color reproduction:

- Design Preparation: A high-resolution digital design is created using software like Adobe Illustrator or CorelDRAW. It must be mirrored before printing

- Printing on Sublimation Paper: The design is printed using special sublimation inks onto transfer paper using an inkjet printer compatible with sublimation.

- Heat Transfer Process: The printed design is placed on the desired product and inserted into a heat press. The typical temperature ranges between 375°F and 400°F.

- Sublimation Reaction: Under high heat and pressure, the ink turns into gas and bonds with the surface, resulting in a smooth, vibrant print.

Stat: Sublimation can reproduce up to 16.7 million colors, offering one of the widest color gamuts in textile printing.

4. What Materials Can Be Used for Sublimation Printing?

Sublimation printing works best on:

- Polyester fabrics (100% polyester yields the best results)

- Polymer-coated hard substrates (e.g., ceramic mugs, aluminum sheets, MDF, and phone cases)

Important Note: Sublimation does not work on cotton or dark fabrics. The process requires light-colored, synthetic surfaces for the ink to bond properly.

Pro Tip: For cotton lovers, hybrid solutions like sublimation on vinyl or using special sublimation coatings are available but come with limitations.

5. What Are the Benefits of Sublimation Printing?

Here are some standout benefits:

- Permanent Design: Ink fuses with the substrate, making prints resistant to fading, cracking, or peeling.

- Photo-Quality Prints: Produces high-resolution, full-color images.

- All-Over Printing: Allows edge-to-edge printing on garments and textiles.

- Eco-Friendly: No water is used in the printing process, and there’s minimal waste.

- Cost-Efficient for Small Batches: Great for short-run custom printing without setup costs.

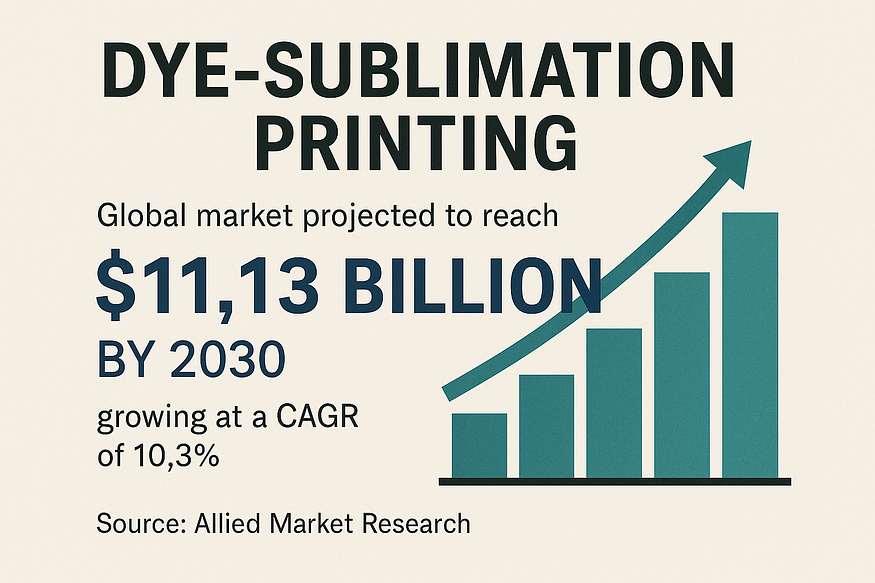

Stat: The global market for dye-sublimation printing is expected to reach $11.13 billion by 2030, growing at a CAGR of 10.3% (Source: Allied Market Research).

6. What Are the Limitations of Sublimation Printing?

Despite its many advantages, sublimation printing has a few drawbacks:

- Material Limitations: Only works well on polyester or polymer-coated items.

- Color Constraints: Best results are achieved on white or light-colored substrates.

- Initial Equipment Cost: Requires a sublimation printer and a heat press.

- Not Suitable for Bulk Cotton Garments: Alternative methods like DTG or screen printing are better suited.

8. Common Uses of Sublimation Printing

Sublimation is widely used across industries due to its versatility. Popular use cases include:

- Custom t-shirts and jerseys

- Mugs, tumblers, and drinkware

- Mousepads, phone cases, and keychains

- Wall art and photo panels

- Polyester home decor like curtains and pillow covers

Fact: Over 70% of custom promotional products are now made using sublimation printing (Source: Printful, 2024).

9. Is Sublimation Printing Right for You?

Sublimation printing is perfect for:

- Entrepreneurs launching custom merchandise brands

- Designers who need detailed, vibrant imagery

- Print shops offering small-batch or on-demand services

You may want to avoid sublimation if:

- You work primarily with cotton textiles

- Your designs require printing on dark fabrics

- You need very large-scale bulk production at low cost

10. FAQs About Sublimation Printing

Q: Can you sublimate on cotton?

A: Not directly. Sublimation requires polyester. Cotton can be used only with special coatings or vinyl.

Q: How long does sublimation printing last?

A: Sublimation prints are permanent and typically last the lifetime of the product.

Q: What kind of printer do you need for sublimation?

A: A dedicated sublimation printer or a converted inkjet printer with sublimation inks.

Q: Is sublimation printing washable?

A: Yes, prints on fabric are fully washable without fading, as the ink is embedded in the fibers.

Q: Is sublimation printing expensive?

A: Not for small runs. While the equipment has an upfront cost, it becomes economical over time.

11. Conclusion

Sublimation printing offers a powerful, vibrant, and long-lasting way to personalize and brand products. With unmatched durability and photo-quality results, it has become a favorite method for both hobbyists and commercial printers alike.

Whether you’re looking to start a custom t-shirt line, print your art on mugs, or add value to your product offerings, understanding what sublimation printing is and how it works is a smart move in 2025.

Ready to start with sublimation? Explore our sublimation printing services or contact our experts to help bring your creative vision to life.

Source Link - https://aestheticbk.weebly.com/blog/what-is-sublimation-printing-and-how-it-works